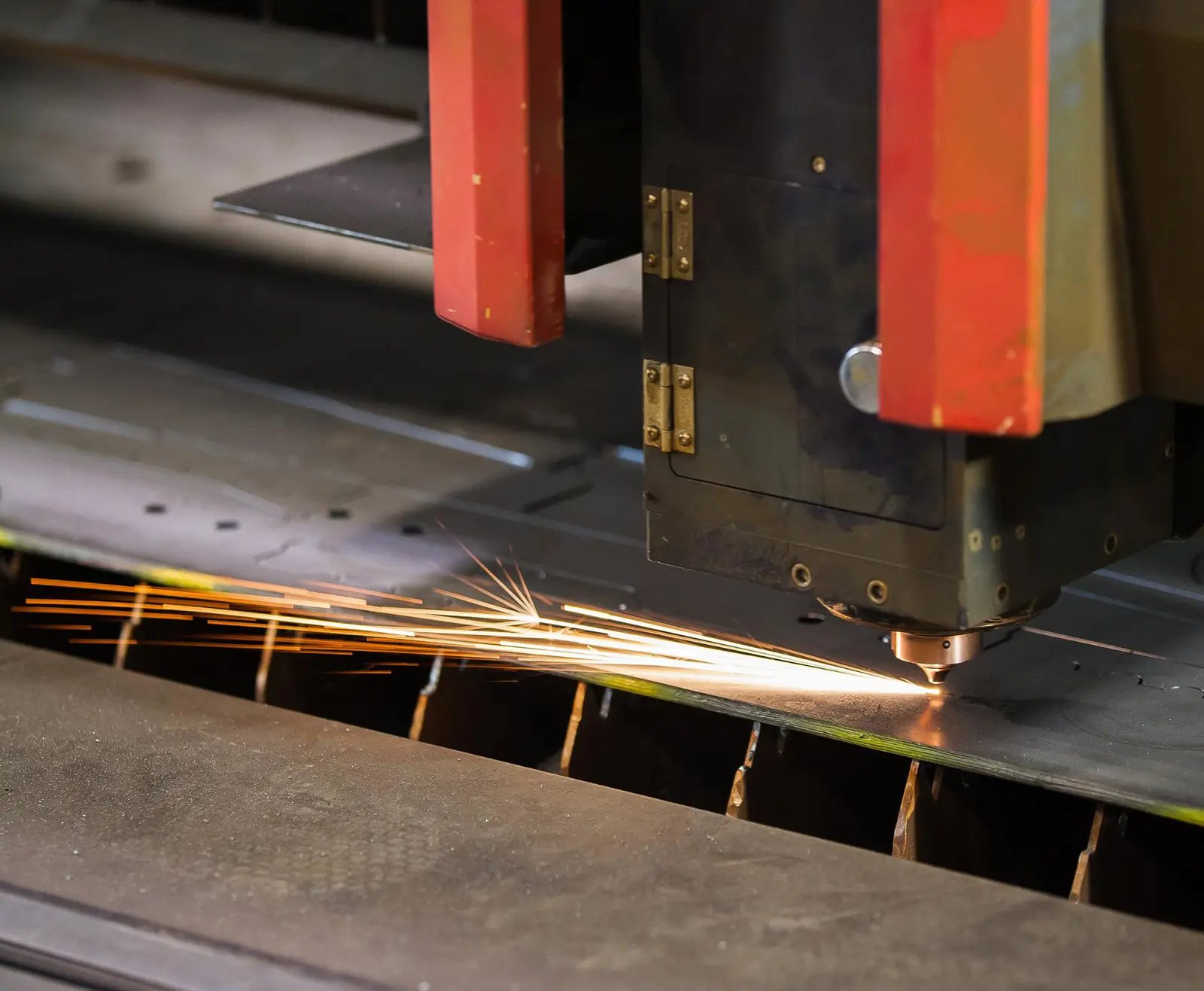

Dynamic, High-Quality Laser Cutting Services for Custom Manufactured Equipment

Amerequip’s precision laser cutting sets the standard for any and all fabrication needs. Our state-of-the-art facility houses six high-end CO₂ laser cutters, fiber laser cutting capabilities, and an expert team, ensuring optimal solutions for every custom equipment application.

Explore our precision laser cutting services below, or contact our team today to discuss your specific requirements.

Expert Laser Cutting Operations

Our precision laser cutting services operate on a tight schedule. Speed, versatility, and precision are achieved by our skilled and experienced operators, with the capacity to run three shifts, including ‘lights out’ capabilities. Behind our skilled operators is the technology that drives superior results.

Our Laser Cutting Features:

- State-of-the-Art Facilities — CO₂ laser cutting centers, including fiber laser cutting capabilities, delivering precision and productivity for your fabrication needs. Our advanced systems handle materials up to 1.0″ thick with accuracies of ±0.010 inch.

- Skilled Workforce — Highly trained operators who know the ins and outs of all our laser systems and keep up to date with new information and best practices.

- Quality Integration — Continuous quality checks performed before, during, and after all laser projects, ensuring the work performed is accurate the first time.

- Advanced Equipment — We utilize six 4500-watt Mitsubishi Lasers, with the capability to expand to 12 total lasers. We also have fiber laser cutting capabilities.

- Responsible Inventory Management — Our operators and team members responsibly manage material inventory storage and perform proper maintenance on all laser loading systems.

- Process Optimization — Streamlined workflows designed to minimize setup time and maximize productivity while maintaining superior quality standards.

Comprehensive Laser Cutting Solutions

Our precision laser cutting services work seamlessly with our vertically integrated manufacturing capabilities, ensuring products are built right the first time, every time. Quality validation occurs at every step, with rigorous inspection protocols that maintain our reputation for excellence.

- Custom Configuration — Laser cutting processes tailored to your specific product requirements and specifications

- Full-Service Vertical Integration — Coordination with our welding services, forming, painting, and assembly capabilities

- Continuous Improvement — Dedicated improvement teams continuously refine processes to enhance efficiency and quality

- Extensive Documentation — Complete records and quality documentation for full traceability

Flexible Cutting Dimensions

Our precision laser cutting services allow for a wide range of cutting depths. Our operators and engineering teams collaborate to establish best practices and solutions to ensure every laser project is accurate and long-lasting.

- Depth and Accuracy — Our lasers cut up to 1.0″ thick carbon steel, with an accuracy of + 0.010 inch.

- Proper Equipment — With a cutting bed of 60” x 120”, we utilize the latest nesting software to maximize sheet steel utilization.

- Quality Is Standard — Operators and engineers maintain the highest quality standards; our ISO 9001:2015 certification is more than just wall art.

Our laser cutting team understands that quality and durability are critical for custom equipment performance. Backed by an ISO 9001:2015 certification and decades of expertise, every laser-cut project exceeds expectations and strengthens your market reputation.