Advanced Engineering Test Services for Product Validation

At Amerequip, we maintain comprehensive engineering test services overseen by our dedicated Test Engineer and specialized technicians. Our robust testing capabilities ensure your custom equipment meets the most demanding performance standards and industry certifications before market introduction.

Explore our extensive testing capabilities below, or contact our team today to discuss your specific validation requirements.

Comprehensive Engineering Test Services

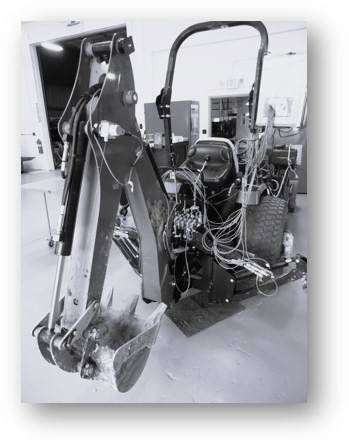

Somewhat unique for a company our size, we offer state-of-the-art engineering test services that validate every aspect of product performance. Our Test Engineer works directly with you to design, plan, and execute testing protocols tailored to your specific requirements, providing confidence that your products will perform reliably under real-world conditions.

Our Testing Capabilities Include:

- Strain Gauge Testing — Precise measurement of stress and strain at critical points, with careful selection of gauge locations based on previous test experience or customer-supplied FEA results

- Data Acquisition Systems — Advanced National Instruments Compac DAQ expandable data acquisition system that captures and analyzes comprehensive performance data

- Environmental Testing — Field testing across 40+ acres of varying terrain with naturally occurring temperature extremes ranging from -20°F to 100°F, simulating virtually any operating condition your product will face

- Hydraulic Testing — Dedicated power units with 4000 psi pumps capable of powering multiple hydraulic circuits simultaneously, complete with flow meters, pressure transducers, and temperature sensors

- Specialized Sensors — Full range of strain gauges, pressure transducers, flow meters, thermocouples, accelerometers, and PLC controllers to handle almost any structural or hydraulic testing need

- Integrated Test Lab — Dedicated prototype shop and product test lab for controlled testing environments

Rigorous Durability and Performance Validation

Our engineering test services include multiple approaches to durability testing, ensuring your products will stand up to the demands of real-world use:

- Cycle Testing — Customer-specified normal load conditions and cycle counts to validate component and system longevity

- Full Function Implement Testing — Expert technicians operate equipment for specified hours to validate design form, fit, and function in actual use cases

- Endurance Testing — Accelerated testing under overload conditions to simulate worst-case scenarios and validate performance margins

- Hydraulic System Validation — Comprehensive testing of hydraulic system performance, pressure regulation, flow characteristics, and thermal management

Industry Certification Testing

We develop products to numerous industry standards, ensuring compliance with all applicable regulations. Our engineering test services team assists with certifications including:

- ISO 4254 — Safety standards for agricultural machinery

- ANSI B71.4 — Safety specifications for commercial turf care equipment

- SAE J31 — Automotive industry standards for hydraulic components

Our commitment to thorough testing goes beyond basic validation, providing documentation and performance data that support your certification requirements and quality assurance programs.

The Amerequip Testing Advantage

By integrating advanced engineering test services with our design and manufacturing capabilities, we deliver a seamless development process that reduces time to market while ensuring exceptional product quality. Our testing protocols identify potential issues early in the development cycle, allowing for cost-effective refinements before production begins.

This comprehensive approach to product validation protects your brand reputation by ensuring your equipment performs reliably in the field, meeting or exceeding end-user expectations from day one.