The Engineering Philosophy That Transforms Ideas Into Reliable Market Leaders

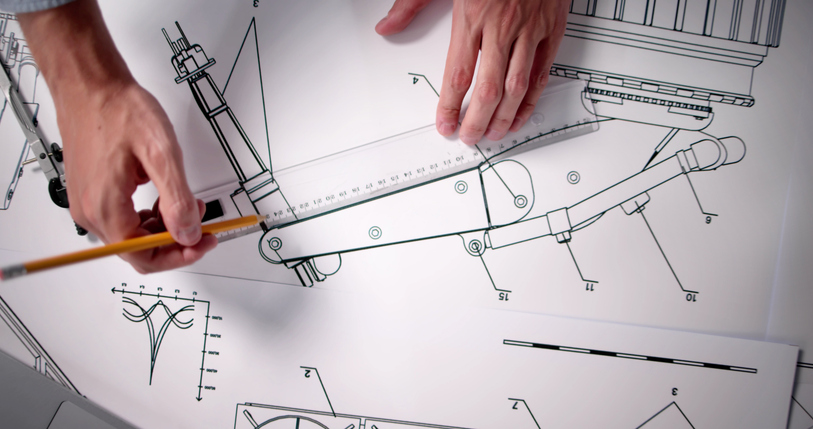

A customer approaches with a revolutionary hydraulic system design that could transform their market position. The concept is brilliant, the potential enormous. There’s just one critical challenge: the design pushes manufacturing boundaries to the breaking point, threatening quality, timelines, and costs. This scenario illustrates the fundamental tension every OEM faces — balancing groundbreaking innovation with practical manufacturability. Equipment design engineering is essential to resolving this tension.

At Amerequip, we’ve spent over 100 years perfecting the art of this balance. Our equipment design engineering approach doesn’t force you to choose between innovation and production reality. Instead, we’ve developed methodologies that amplify both, creating products that lead markets while meeting the demanding requirements of consistent, cost-effective manufacturing.

Transform innovative concepts into production-ready solutions: Partner with Amerequip’s integrated design and manufacturing expertise for equipment that excels in both performance and producibility.

The Innovation Trap That Derails Product Development

Many engineering teams fall into what we call the “innovation trap” — developing cutting-edge designs in isolation from manufacturing constraints. The result? Concepts that wow in presentations but struggle in production, leading to costly revisions, delayed launches, and compromised performance.

Traditional equipment design engineering processes create artificial barriers between innovation and manufacturability. Engineers focus on pushing performance boundaries while manufacturing teams inherit the challenge of making complex designs practical. This sequential approach often forces difficult compromises that diminish both innovation potential and production efficiency.

The Amerequip Equipment Design Engineering Advantage: Integrated Philosophy

Our equipment design engineering approach eliminates this false choice through an integrated methodology that considers manufacturing constraints as design opportunities rather than limitations. When your engineers work alongside our team, they gain access to manufacturing insights that enhance innovation potential.

Our experienced design team utilizes advanced CAD systems — such as CREO Direct, CREO Parametric, and SolidWorks — combined with direct manufacturing knowledge to maximize DFM (Design for Manufacturability) considerations. This isn’t just design work; it’s strategic innovation that strengthens your competitive position.

What sets our approach apart is the seamless integration between design creativity and manufacturing reality. Our capability to export CAD files directly to production equipment means we design with a complete understanding of how concepts will translate to finished products. This knowledge enables innovations that might seem impossible to teams working without manufacturing integration.

VA/VE Projects: Optimizing Value Throughout Development

Our Value Analysis and Value Engineering (VA/VE) methodology systematically optimizes product value by reducing costs while improving functionality. This approach applies throughout the product lifecycle, from initial concept through production refinement.

During Value Analysis, we examine existing designs to identify improvement opportunities that enhance both performance and manufacturability. Our Value Engineering process integrates cost optimization directly into new product development, ensuring innovations deliver maximum market impact within practical production parameters.

This systematic equipment design engineering approach prevents the costly design iterations that occur when manufacturability becomes an afterthought. Instead, we optimize both dimensions simultaneously, delivering products that exceed performance expectations while meeting aggressive cost targets.

Design for Manufacturability: Innovation Through Constraint

Rather than limiting creativity, Design for Manufacturability (DFM) principles actually expand innovation possibilities by providing clear parameters for optimization. Our engineering team brings deep manufacturing knowledge to every design decision, identifying opportunities to enhance both product performance and production efficiency.

Our multi-platform CAD capabilities enable innovative collaboration while ensuring design compatibility across different systems. Through IGES and STEP file conversion, we work seamlessly with your existing platforms while bringing manufacturing insights that enhance design potential.

Real-time cost management throughout the design cycle, supported by leading software, ensures projects maintain target financial metrics without compromising innovation goals. This ongoing optimization prevents costly surprises and enables more aggressive innovation within practical constraints.

Build Your Equipment Design Engineering Advantage With Amerequip

The most successful OEMs understand that sustainable competitive advantage comes from products that lead markets while meeting practical production requirements. Amerequip’s equipment design engineering approach delivers both dimensions through proven methodologies refined over decades of manufacturing excellence.

Our mission — “Never Compromising our Customers’ Reputation” — drives every design decision we make. When innovation and manufacturability work together rather than against each other, the result is equipment that strengthens your market position while protecting your reputation for quality and reliability.

Ready to discover how integrated design engineering can amplify your innovation potential? Contact our engineering team today to explore how Amerequip’s comprehensive approach can transform your next breakthrough concept into a market-leading reality.