When your project needs additional services, and accuracy, quality, precision, and efficiency are non-negotiable, there’s only one solution to turn to.

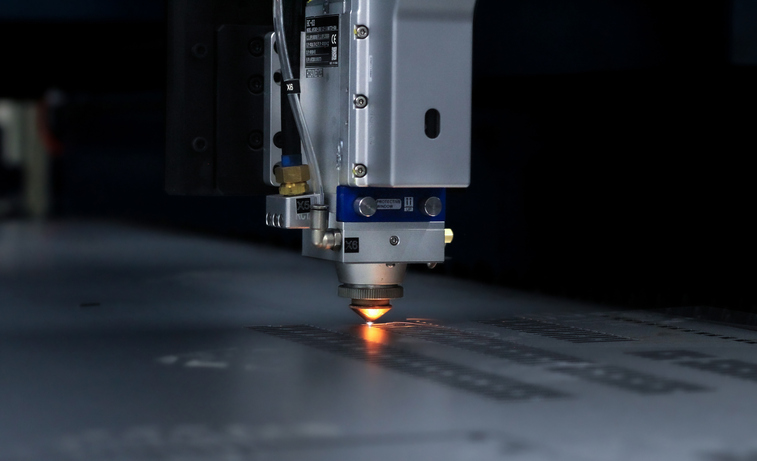

CO2 laser cutting involves a blend of science and artful skill. Manufacturers rely on CO2 lasers to create the finest cuts and deliver detail with accuracy and quality.

Amerequip details how CO2 laser cutting works, why it’s needed, and its best applications.

How CO2 Laser Cutting Works

This style of laser cutting is powered by carbon dioxide. It’s the most essential part of the service, as this is how the beam is generated.

A tube is filled with the CO2 element along with an assortment of other gases that become electrified to create a radiated beam, which serves as the laser. The energy from the beam is directed by a series of mirrors into a focusing lens, which aims the beam onto the targeted spot on the material.

The laser gives off heat, which is what changes the material by melting or vaporizing it.

Why CO2 Laser Cutting is Needed

Not just CO2 lasers, but all lasers in manufacturing, are needed for precise, accurate, and efficient cutting. But that’s only scratching the surface of the benefits.

Utilizing CO2 laser services means opting for high precision and accuracy for the most detailed shapes. Computers control accuracy and precision, as well as how narrow the beam is.

Contactless cutting reduces damage from wear or force. Because the process is more accurate than other cutting methods, like CNC machining or waterjetting, CO2 laser cutting minimizes unintentional damage to the material.

CO2 laser cutting works on multiple materials, including metals, plastics, woods, and more. Even the most dense materials allow for CO2 laser cutting, as the energy from the beam can cut through most materials with minimal difficulty.

This style of laser cutting happens at a fast rate, making it efficient, repeatable, and automated, if necessary. It’s another way for Amerequip to get your product into the market faster.

Because products are cut cleanly and smoothly, and contain precise edges with minimal heat-affected zones, CO2 laser cutting helps manufacturers avoid post-processing and secondary services.

Best and Common Applications

This style of laser cutting is commonly used in industrial products, but its applications go beyond that.

It can be used to cut sheet metal, plastics, and other materials for multiple industries, including automotive, aerospace, electronics, heavy equipment, and more.

CO2 laser cutting is used in the medical field by surgeons for cutting into tissue, cauterizing, and skin resurfacing. More and more healthcare professionals are gaining access to laser cutting capabilities, helping patients experience faster recoveries.

Contact Amerequip Today for Your CO2 Laser Cutting Needs

Amerequip is a leading heavy equipment manufacturer, and for over 100 years, we’ve continued to push boundaries and expand our capabilities. CO2 laser cutting is one of the things we do best in our headquarters in Kiel, Wisconsin.

Our laser cutting facility features six 4500-watt Mitsubishi lasers, and that’s only the beginning of our capabilities. Backed by our ISO 9001 certification, you can have confidence in the laser cutting work performed by our skilled team.

Contact Amerequip today for your CO2 laser cutting needs and explore more of what we can do for you.