Streamline Your Production With Our In-House Turnkey Solutions

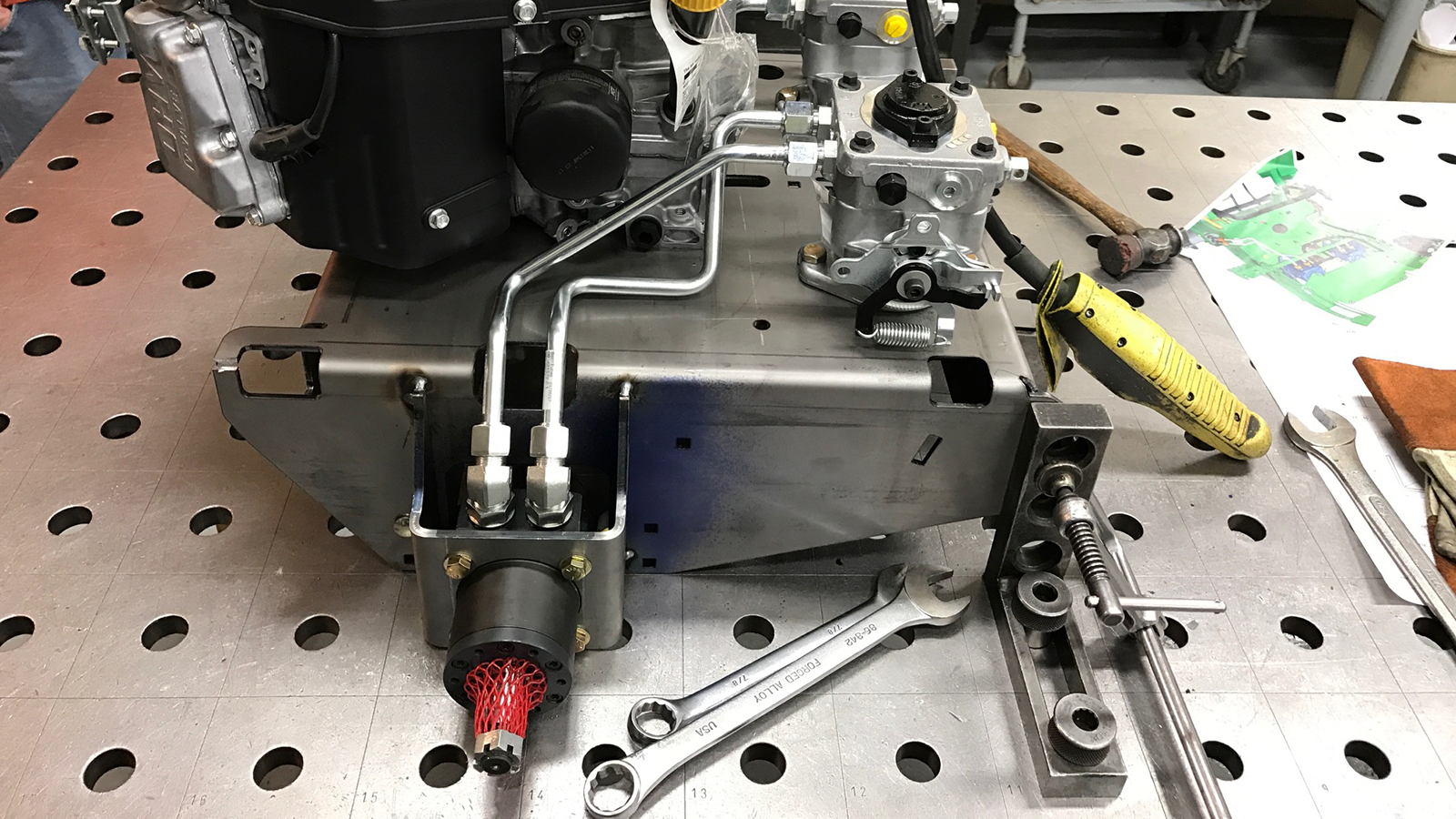

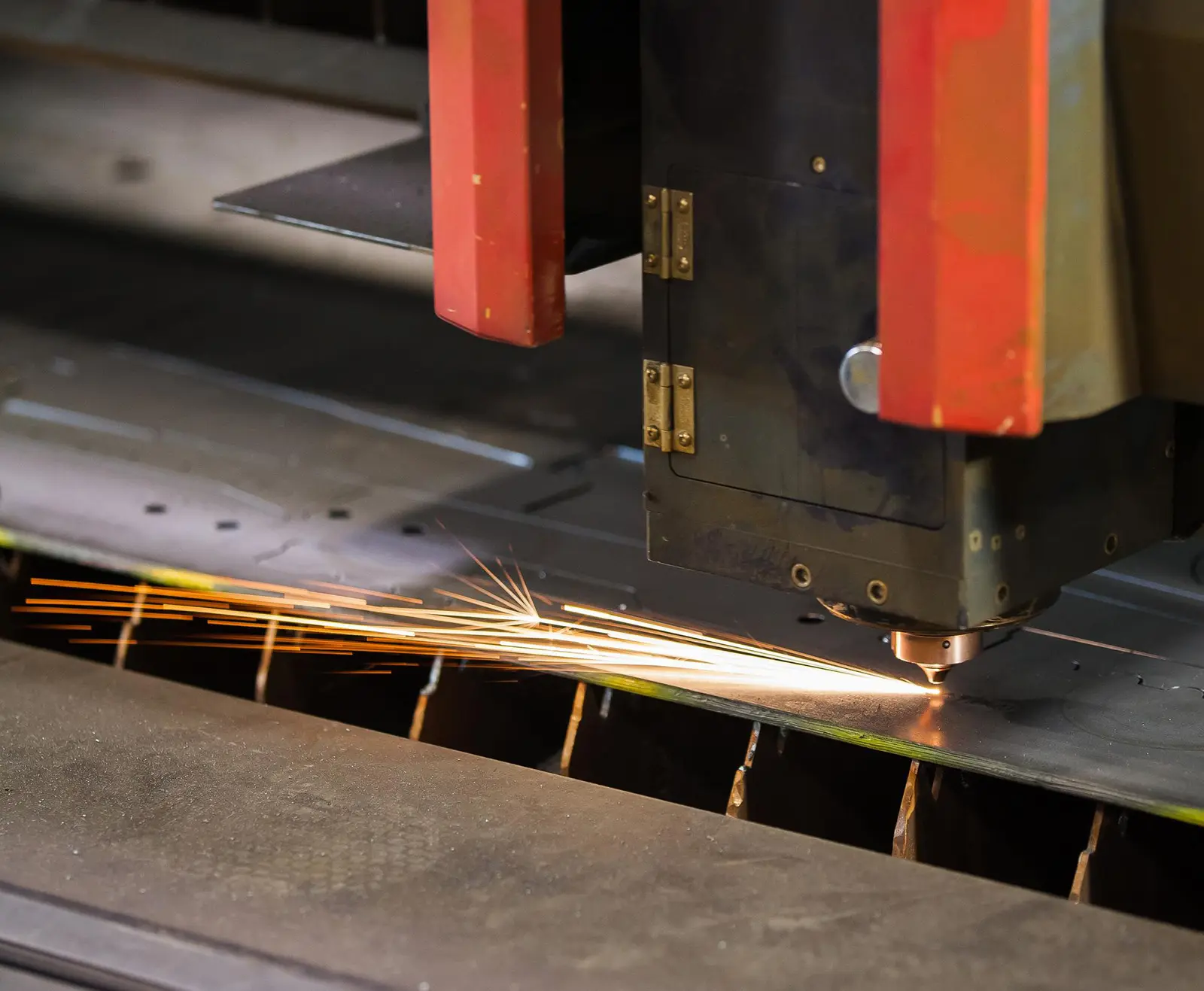

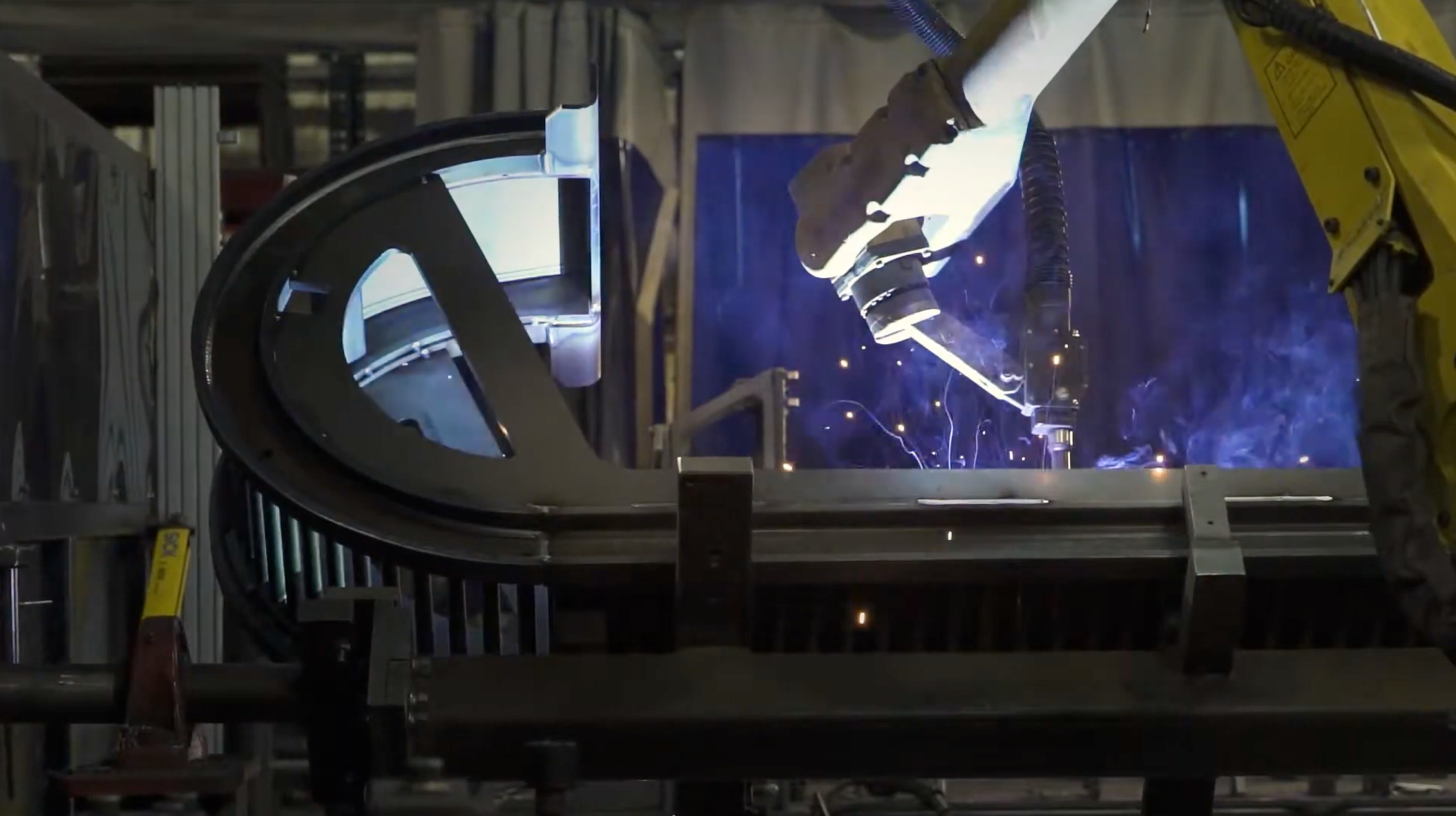

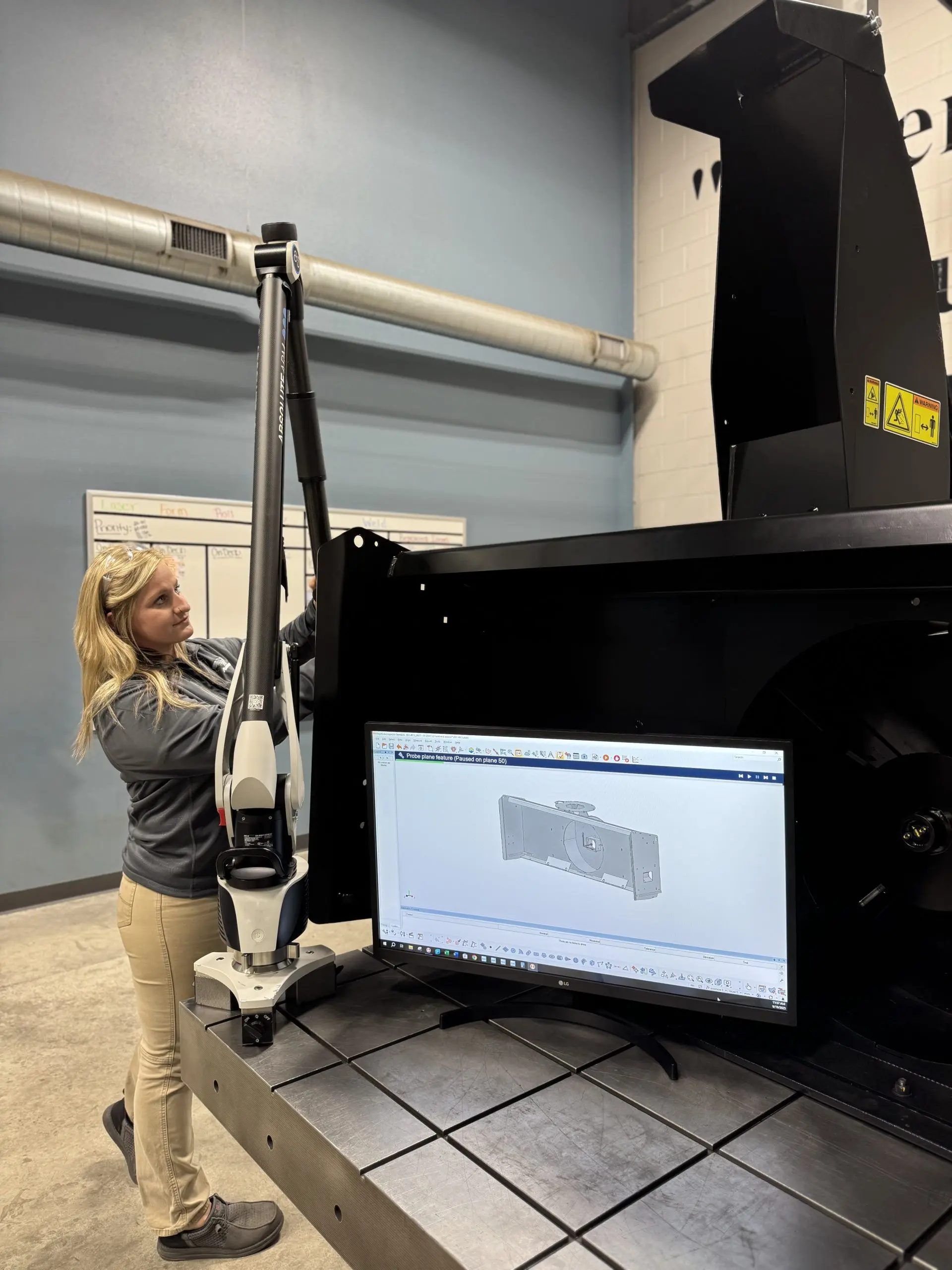

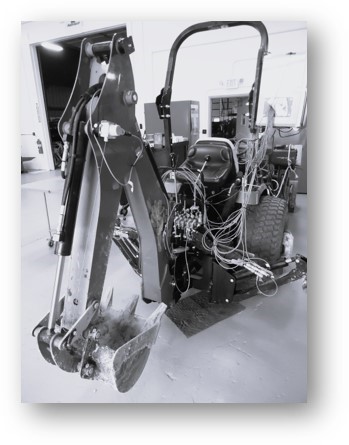

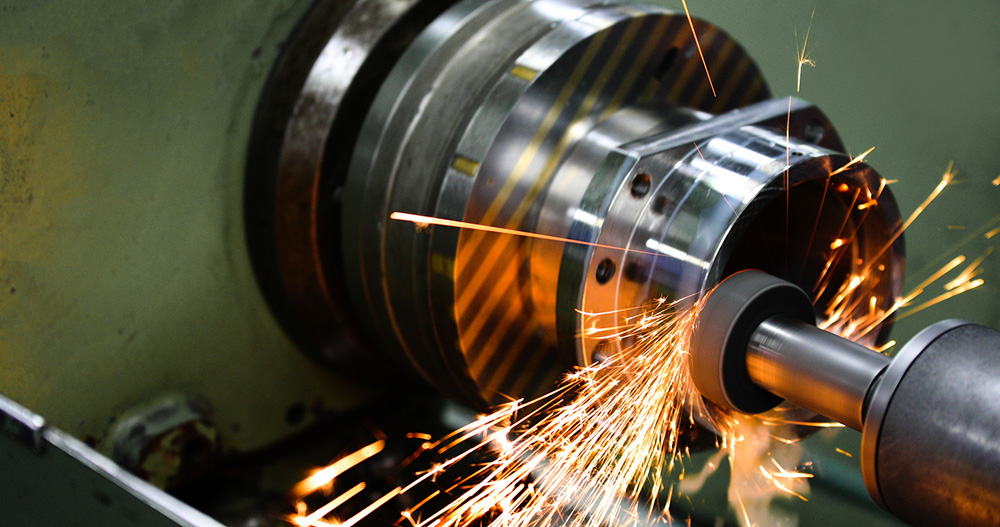

At Amerequip, our vertically integrated manufacturing capabilities deliver precision, quality, and efficiency at every stage of production. Our state-of-the-art facilities and expert teams ensure complete control over your custom equipment manufacturing needs, from initial components to final assembly.

Our comprehensive in-house capabilities minimize lead times and maximize quality control. With over 400,000 square feet of manufacturing space and industry-leading technology, we deliver superior results for the most demanding applications.

We’ve invested in advanced technology and skilled teams across every manufacturing discipline, ensuring exceptional quality and precision throughout the production process. Explore our custom equipment manufacturing capabilities below, or reach out to our team today to learn more about our design, engineering, and manufacturing services.