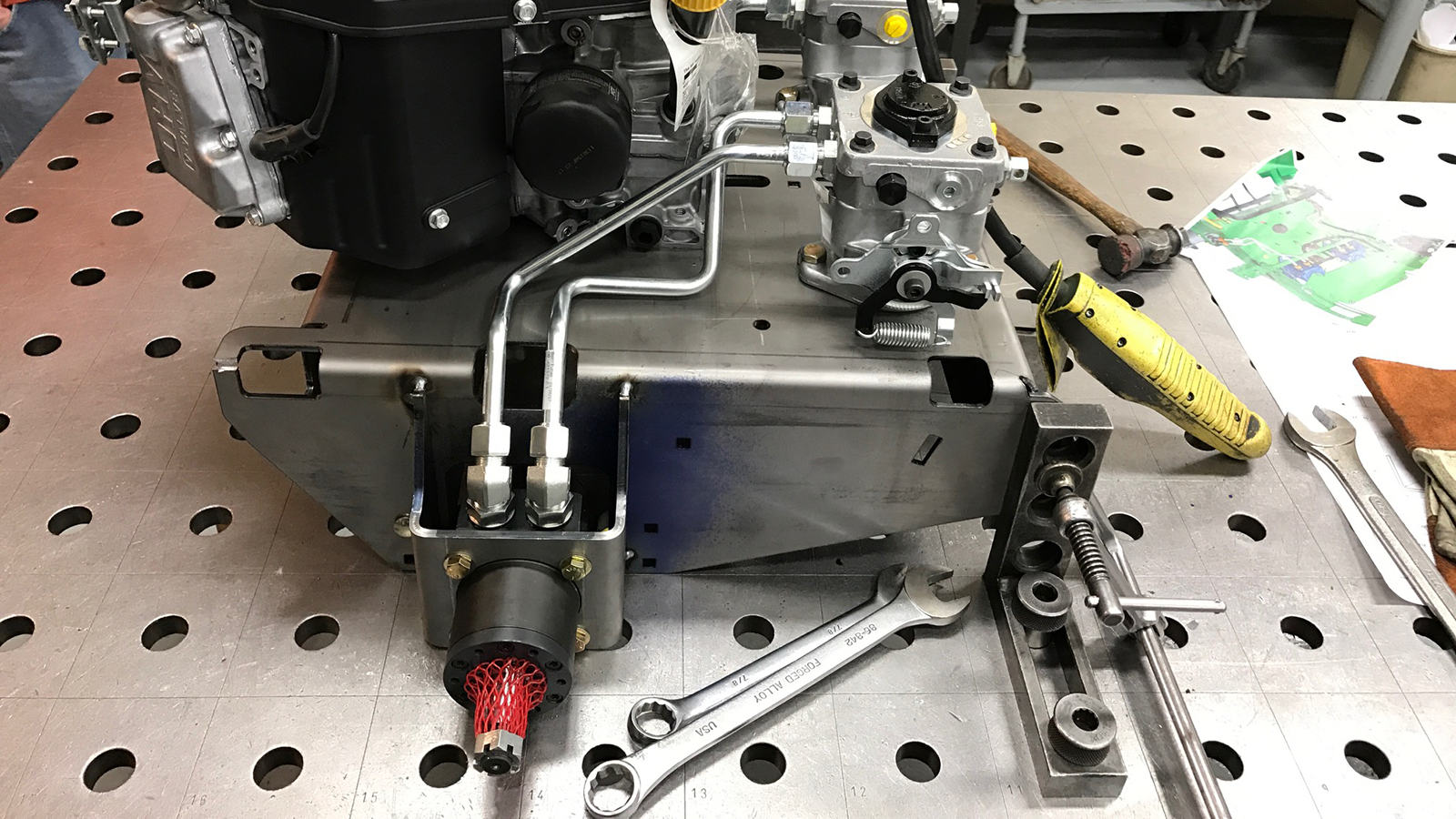

Accelerate Your Product Development With Rapid Prototype Manufacturing

At Amerequip, our dedicated team provides rapid prototype manufacturing in the fabrication and assembly of your proposed product, helping you reduce time to market and make critical design decisions with confidence. We utilize our actual production equipment — lasers, forming, welding, and paint lines — to deliver true final-product representation that validates both form and function.

Explore our rapid prototype manufacturing capabilities below, or contact our team today to discuss your specific needs.

True-to-Production Rapid Prototype Manufacturing

Unlike typical prototyping services that use specialized equipment or processes different from final production, Amerequip’s approach provides a genuine preview of your product’s production reality. This unique advantage eliminates surprises during manufacturing scale-up and ensures a smooth transition from prototype to full production.

Our Rapid Prototype Manufacturing Capabilities Include:

- Dedicated Prototype Team — Experienced specialists focused exclusively on rapid turnaround of prototype projects

- Production-Grade Equipment — Using the same lasers, forming equipment, welding cells, and paint lines as your final production run

- Materials Consistency — Working with identical materials to your production specifications for accurate performance testing

- Assembly Verification — Validating assembly processes and ergonomics before committing to production tooling

- Comprehensive Documentation — Detailed reporting on prototype performance, manufacturing observations, and improvement opportunities

- Design for Manufacturability (DFM) — Expert analysis of your designs for production optimization and cost efficiency

The Strategic Value of Professional Prototyping

Investing in proper rapid prototype manufacturing delivers substantial benefits throughout your product development cycle:

- Accelerated Development — By rapidly testing and refining designs, you can drastically reduce your overall time to market

- Risk Reduction — Identifying and resolving potential manufacturing challenges before committing to production tooling and processes

- Enhanced Performance Validation — Actual production-grade prototypes allow for meaningful real-world testing and performance verification

- Stakeholder Alignment — Physical prototypes facilitate clearer communication with internal teams, customers, and other stakeholders

- Manufacturing Optimization — Insights gained during prototyping guide production refinements that improve quality and reduce costs

Product Validation and Verification

We recognize that thorough PV&V (Product Validation and Verification) testing is critical before introducing new products to the market. Our prototype manufacturing capabilities integrate seamlessly with our comprehensive testing services, including strain gauge testing, durability assessment, and field testing across varied terrain and temperature conditions.

By combining rapid prototype manufacturing with rigorous validation, Amerequip helps ensure your final product meets both performance requirements and manufacturing efficiency targets. This holistic approach minimizes development cycles while maximizing product quality and market readiness — and is just one component of our vertically integrated manufacturing capabilities.