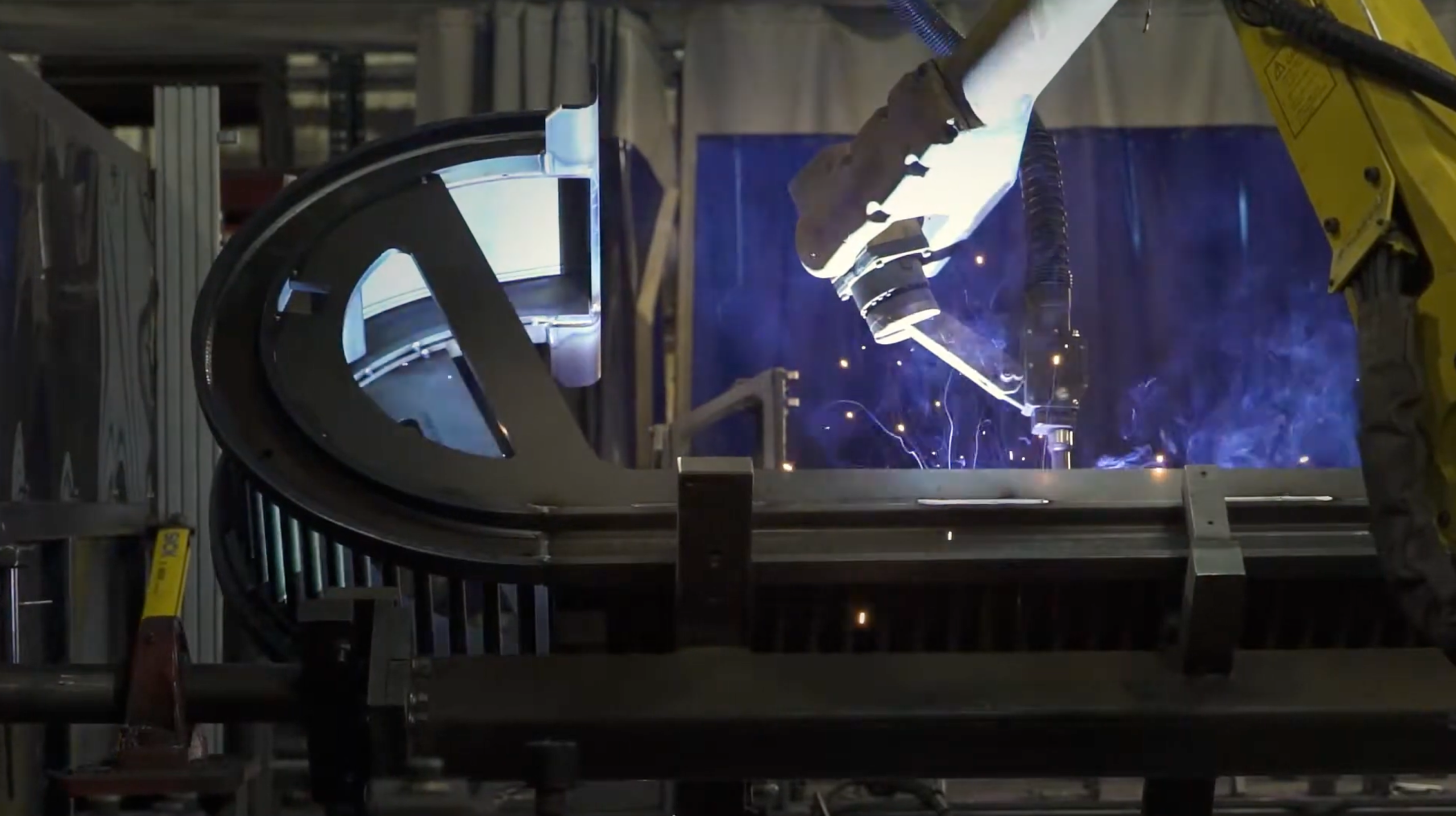

Accurate, High-Quality Robotic Welding Services for Custom Equipment Excellence

Amerequip’s robotic welding services combine cutting-edge automation with skilled craftsmanship to deliver exceptional quality and consistency. Our 75,000-square-foot welding facility houses high-speed robotic welders alongside expert manual welding professionals, ensuring optimal solutions for every custom equipment application.

Explore our robotic welding services below, or contact our team today to discuss your specific requirements.

Expert Robotic Welding Operations

Our robotic welding services follow tight guidelines to best ensure accuracy, detail, and serve as a cost-effective measure for customers. Our skilled workforce combines expertise in both robotic and manual welding techniques, providing comprehensive solutions that meet the most demanding custom equipment specifications.

Our Robotic Welding Features:

- State-of-the-Art Facilities — Our 75,000-square-foot welding facility provides extensive production capacity with the latest robotic welding technology.

- Skilled Workforce — Highly trained welders who understand the ins-and-outs of both robotic and manual welding services.

- Quality Integration — Continuous quality checks throughout the welding process with dedicated Weld Engineer inspections and process validations

- Advanced Equipment — High-speed robotic welders efficiently construct reliable, repeatable welds using fixtures and tooling made by Amerequip technicians.

- Responsible Design Practices — Our in-house Weld Engineer designs welding procedures and practices in coordination with the requirements of our Engineering Department.

- Process Optimization — Streamlined workflows designed to minimize setup time and maximize productivity while maintaining superior quality standards

Comprehensive Welding Solutions

Our robotic welding services integrate seamlessly with our vertically integrated manufacturing capabilities, ensuring products are built right the first time, every time. Quality validation occurs at every step, with rigorous inspection protocols that maintain our reputation for excellence.

- Custom Configuration — Welding processes tailored to your specific product requirements and specifications

- Full-Service Vertical Integration — Coordination with our laser cutting, forming, painting, and assembly capabilities

- Continuous Improvement — Dedicated improvement teams continuously refine processes to enhance efficiency and quality

- Extensive Documentation — Complete records and quality documentation for full traceability

Tight Procedure Standards

Our robotic welding services adhere to stringent procedures and standards. Our welding and engineering teams collaborate to establish best practices and solutions to ensure every weld that is accurate, long-lasting, and requires minimal rework.

- Consistent Weld Penetration — Uniform penetration depth and quality across all welded joints

- Uniform Weld Appearance — Professional finish quality with consistent bead appearance and profile

- Repeatable Weld Quality — Keeping weld joints throughout the product consistent in strength and appearance is critical and part of our work.

Our robotic welding team understands that quality and durability are critical for custom equipment performance. Backed by an ISO 9001:2015 certification and decades of expertise, every welded product exceeds expectations and strengthens your market reputation.